crystal@jsjhhsteel.com +8613327905558 102 Bldg A, 7# nongshi Rd, DongbeiTang,Xishan Dist, Wuxi,Jiangsu,CHINA

English

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

Monel 401 Plate/Pipe/Bar

Monel 401 Plate/Pipe/Bar are a category of high-performance bars made from a special metal alloy known as Monel, which is primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. The two most common types of Monel are Monel 400 and Monel K500. These materials are notable for their excellent corrosion resistances and other desirable properties.

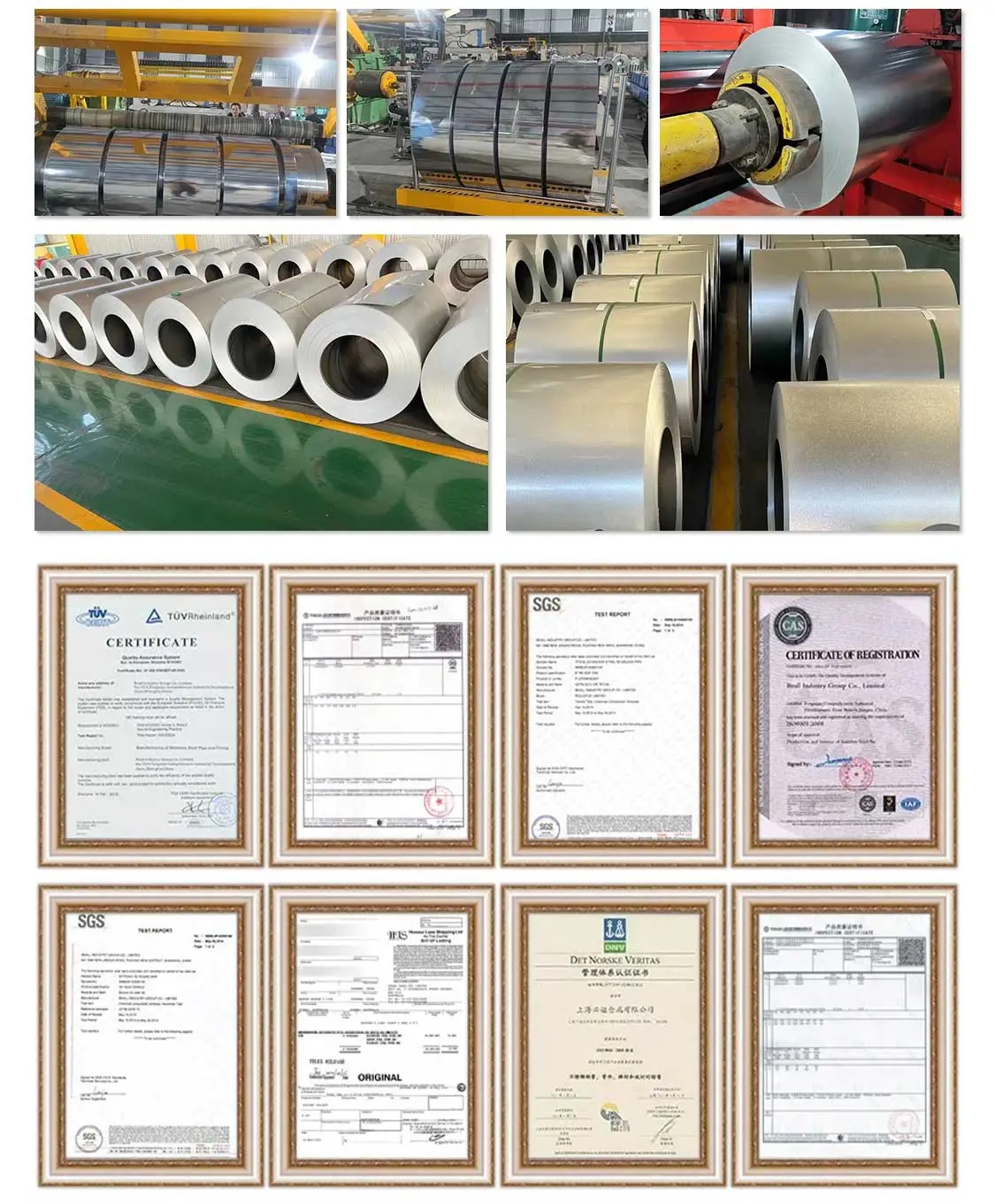

Metal supplier,stockist and manufacturer

We offer an extensive product line including various alloys, stainless steel, carbon steel and copper. Our alloy product portfolio includes alloy steels, aluminum alloys, nickel-based alloys, and more. Our stainless steel and carbon steel products are available in different grades and sizes to meet different industry needs. We also offer copper in various forms including sheet, bar, tube and custom shapes.

Professional service team

Our service team is the backbone of the customer relationship, ensuring every interaction with our company is seamless, informative and satisfying. With a customer-centric approach, our professionals provide end-to-end support, from handling queries to after-sales services, ensuring your complete satisfaction at every step.

Expert technical team

Our company's technical prowess is unparalleled. Our team of engineers and technicians bring years of experience and a passion for innovation to produce metal with precision and care. Their expertise ensures our products can withstand the rigorous demands of any application, delivering reliability and performance.

here's an expanded table with eight common Hastelloy Bar models and their applications.

These are simplified descriptions of each model and their usual applications. The actual use cases can vary based on requirements, and there may be other Hastelloy alloys more suitable for specific industrial needs.

here's that information in a table format.

| Model | Applications |

|---|---|

| Monel 400 | Used in marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, heat exchangers, and fasteners. This material is notable for its excellent corrosion resistance. |

| Monel 401 | Known for its easy machinability, used predominantly in applications where heavy machining is required. |

| Monel R-405 | The presence of more sulfur gives it greater machinability. Mainly used for automatic screw machine stock where extensive machining is needed. |

| Monel K-500 | Strengthened by aluminum and titanium, it's utilized in pump shafts, doctor blades and scrapers, oil well drill collars and instruments, electronic components, springs, and valve trims. Its high strength and hardness make it particularly suitable. |

| Monel 404 | Primarily used in situations needing a low coefficient of thermal expansion, such as electronic components and other temperature-critical applications. |

| Monel 405 | Essentially identical to 400 but with more sulfur for better machinability. Used in automatic screw machine products. |

| Monel 502 | Used in the parts that require high strength and hardness, and in the manufacturing of gas turbine engines due to its enhanced mechanical properties. |

| Monel 450 (Alloy 450) | Offers high resistance against a variety of corrosives, particularly used in desalination plants handling water with high chloride contents. |

Monel 401 Plate/Pipe/Bar production process

The production begins with the appropriate ratio of nickel, copper, and smaller amounts of other elements like iron, manganese, carbon, and silicon. The unique elemental composition contributes to the unique properties of Monel. In the case of Monel K500, additional aluminium and titanium are included.

Melting: The raw materials are put into a furnace and melted at high temperatures. The molten mixture is then cast into a billet or ingot. This is a semi-finished form that will be further processed into the final product.

Hot Rolling: The cast ingot or billet is hot-rolled while it's still relatively hot. This process reduces the cross-sectional area of the billet, elongating it and giving it a rough bar shape. Hot rolling also helps to refine the grain structure and improve the material's mechanical properties.

Cold Finishing: After hot rolling, the bar may go through a cold finishing process. This involves room-temperature operations such as cold drawing or turning, grinding, and polishing, which help to improve dimensional accuracy, surface quality, and mechanical properties.

Heat Treatment: Depending on the specific version of Monel, the bars might go through a heat treatment process. This can include annealing (to relieve internal stresses and improve ductility) or age-hardening (to increase strength and hardness, as in the case of Monel K500).

Inspection and Testing: Quality control is a vital part of the process. Each bar is inspected for any flaws or defects. There might also be mechanical testing (for properties like tensile strength, yield strength, and elongation), corrosion resistance testing, and other forms of analysis to ensure the bars meet the required specifications.

Final Processing and Packaging: The final step involves finishing processes, like straightening and cutting the bars to desired lengths, and packaging for transport to the customer. Some bars might also receive a layer of coating or plating to help protect against surface corrosion during storage and shipping.

Our advantage

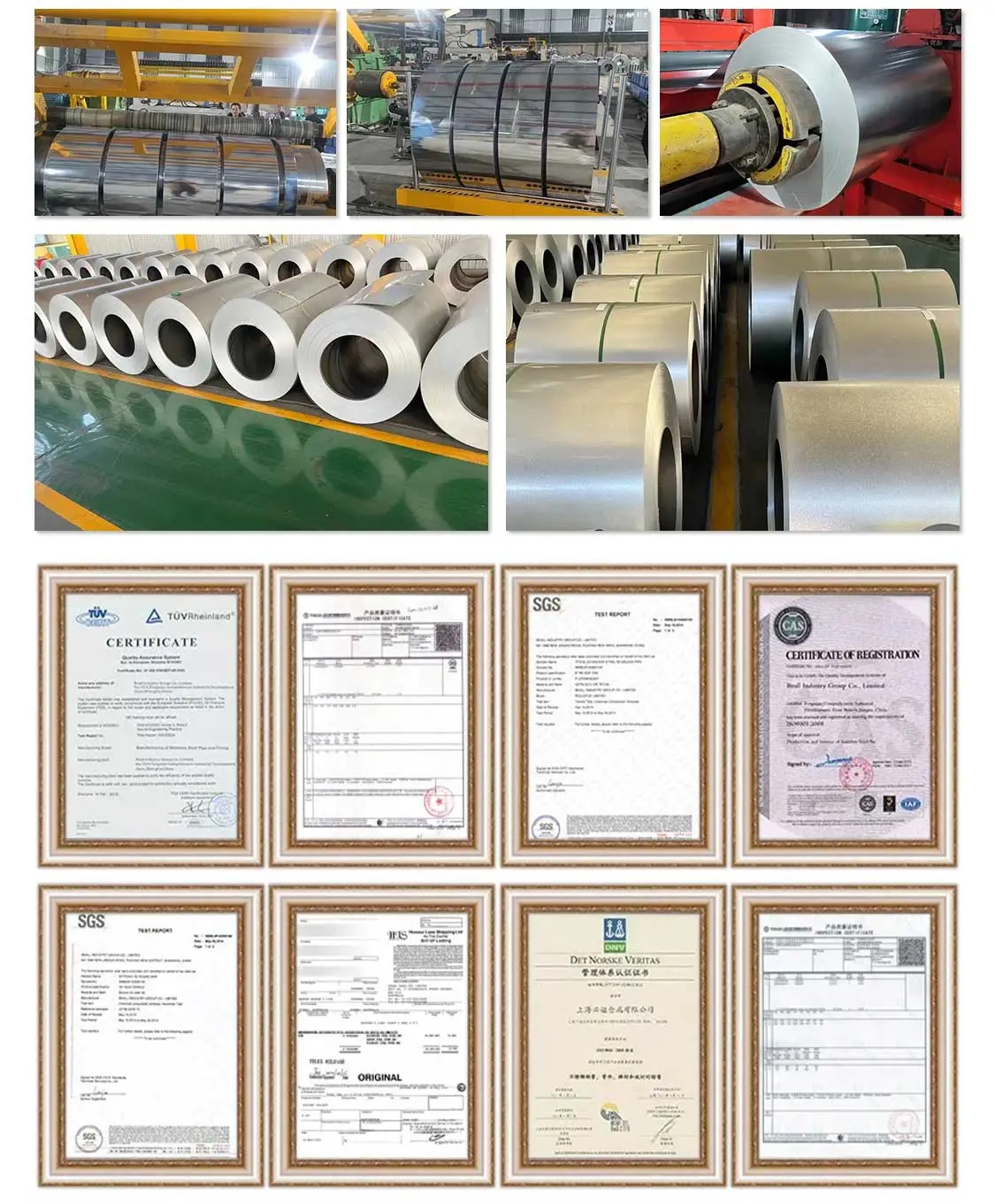

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Monel 401 Plate/Pipe/Bar Chemical Composition

Monel 401 is known for its unique composition that resists the corrosive effects of rapidly moving seawater. It's often used in marine applications, but information about its exact chemical composition are restricted and not publicly available.

Monel 401 Chemical Composition

However, we can make an educated guess based on the compositions of Monel 400 and other common Monel alloys:

Nickel (Ni): 63% (minimum)

Copper (Cu): 28-34%

Iron (Fe): 2.5% max

Manganese (Mn): 2% max

Carbon (C): 0.3% max

Monel 401 Applications

Monel 401 is designed for a specific range of applications that require a specific electrical resistance and a smooth surface finish.

Common Applications include:

Paddles for seawater applications

Meter and valve parts

Electrical and electronic components

Equipment used in wire-wrapped drilling applications

Oil well tooling and marine propeller shafts

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31; | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Series: | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20; | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Product Characteristics | 1.According to the preparation process can be divided into deformation superalloys, casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| Packaging | 1. cases packed in wooden cases 2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

| Delivery | Within 7-15 days |

| Payment | L/C, T/T (30% deposit) |

Common forms of Monel bars

Monel bars are available in a variety of shapes and forms. Here are the common forms:

Round Bars: These are solid, cylindrical bars that are often used in machining and tooling applications or for products that require things like shafts, pins, or rods.

Square Bars: Square bars are solid bars with a square cross-section. They can be used in fabrications, in machine parts, or in structures.

Flat Bars: Flat bars feature a flat, rectangular cross-section. They are commonly used in construction for building frameworks or in manufacturing machinery parts due to their excellent strength-to-weight ratio.

Hexagonal Bars: Hex bars are another form that provides strength and excellent machinability. They are commonly used in nuts, bolts, fasteners, sprockets, and other such applications where the additional facets are useful.

Rectangular Bars: These are similar to flat bars but have a squarer or more substantial rectangular cross-section. They are often used in structural applications.

The choice among these forms largely depends on the specific application and requirements, including the kind of processing needed (such as cutting, drilling, welding), and the expected loads and stresses.

Monel bars offer a range of advantages due to the inherent properties of the Monel 400 alloy. Here are some of them:

Corrosion Resistance: Monel bars are highly resistant to corrosion, making them suitable for use in highly corrosive environments, such as oil and gas production, marine environments and chemical processing facilities.

High Strength: Monel bars possess good strength and toughness over a wide temperature range, making them suitable for applications that require high strength, such as fasteners and springs.

Excellent Weldability: Monel is readily weldable by most standard processes, which means that Monel bars can easily be shaped into complex structures as needed.

Thermal Stability: Monel bars have good thermal stability; they retain much of their strength at high temperatures, which makes them suitable for use in applications with high thermal demands.

Mechanical Properties: The alloy can be fully used at very low temperatures without a loss of mechanical properties. This makes it suitable for cryogenic applications.

Versatility: Because Monel bars can be obtained in a variety of shapes – rounds, squares, flats, hexagonals – they are versatile materials that can be used in a wide variety of applications.

Long-Lasting: Due to their inherent corrosion resistance and strength, products made from Monel alloy often have a longer lifespan than equivalent products made from less resistant materials.

However, the use of Monel 400, like any material, should be carefully matched to the application, environment, and required properties. Monel 400 is also generally more expensive than standard stainless steel or other common materials, and this cost factor should be taken into account in any decision to use it.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.

Monel 401 Plate/Pipe/Bar

Monel 401 Plate/Pipe/Bar are a category of high-performance bars made from a special metal alloy known as Monel, which is primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. The two most common types of Monel are Monel 400 and Monel K500. These materials are notable for their excellent corrosion resistances and other desirable properties.

Metal supplier,stockist and manufacturer

We offer an extensive product line including various alloys, stainless steel, carbon steel and copper. Our alloy product portfolio includes alloy steels, aluminum alloys, nickel-based alloys, and more. Our stainless steel and carbon steel products are available in different grades and sizes to meet different industry needs. We also offer copper in various forms including sheet, bar, tube and custom shapes.

Professional service team

Our service team is the backbone of the customer relationship, ensuring every interaction with our company is seamless, informative and satisfying. With a customer-centric approach, our professionals provide end-to-end support, from handling queries to after-sales services, ensuring your complete satisfaction at every step.

Expert technical team

Our company's technical prowess is unparalleled. Our team of engineers and technicians bring years of experience and a passion for innovation to produce metal with precision and care. Their expertise ensures our products can withstand the rigorous demands of any application, delivering reliability and performance.

here's an expanded table with eight common Hastelloy Bar models and their applications.

These are simplified descriptions of each model and their usual applications. The actual use cases can vary based on requirements, and there may be other Hastelloy alloys more suitable for specific industrial needs.

here's that information in a table format.

| Model | Applications |

|---|---|

| Monel 400 | Used in marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, heat exchangers, and fasteners. This material is notable for its excellent corrosion resistance. |

| Monel 401 | Known for its easy machinability, used predominantly in applications where heavy machining is required. |

| Monel R-405 | The presence of more sulfur gives it greater machinability. Mainly used for automatic screw machine stock where extensive machining is needed. |

| Monel K-500 | Strengthened by aluminum and titanium, it's utilized in pump shafts, doctor blades and scrapers, oil well drill collars and instruments, electronic components, springs, and valve trims. Its high strength and hardness make it particularly suitable. |

| Monel 404 | Primarily used in situations needing a low coefficient of thermal expansion, such as electronic components and other temperature-critical applications. |

| Monel 405 | Essentially identical to 400 but with more sulfur for better machinability. Used in automatic screw machine products. |

| Monel 502 | Used in the parts that require high strength and hardness, and in the manufacturing of gas turbine engines due to its enhanced mechanical properties. |

| Monel 450 (Alloy 450) | Offers high resistance against a variety of corrosives, particularly used in desalination plants handling water with high chloride contents. |

Monel 401 Plate/Pipe/Bar production process

The production begins with the appropriate ratio of nickel, copper, and smaller amounts of other elements like iron, manganese, carbon, and silicon. The unique elemental composition contributes to the unique properties of Monel. In the case of Monel K500, additional aluminium and titanium are included.

Melting: The raw materials are put into a furnace and melted at high temperatures. The molten mixture is then cast into a billet or ingot. This is a semi-finished form that will be further processed into the final product.

Hot Rolling: The cast ingot or billet is hot-rolled while it's still relatively hot. This process reduces the cross-sectional area of the billet, elongating it and giving it a rough bar shape. Hot rolling also helps to refine the grain structure and improve the material's mechanical properties.

Cold Finishing: After hot rolling, the bar may go through a cold finishing process. This involves room-temperature operations such as cold drawing or turning, grinding, and polishing, which help to improve dimensional accuracy, surface quality, and mechanical properties.

Heat Treatment: Depending on the specific version of Monel, the bars might go through a heat treatment process. This can include annealing (to relieve internal stresses and improve ductility) or age-hardening (to increase strength and hardness, as in the case of Monel K500).

Inspection and Testing: Quality control is a vital part of the process. Each bar is inspected for any flaws or defects. There might also be mechanical testing (for properties like tensile strength, yield strength, and elongation), corrosion resistance testing, and other forms of analysis to ensure the bars meet the required specifications.

Final Processing and Packaging: The final step involves finishing processes, like straightening and cutting the bars to desired lengths, and packaging for transport to the customer. Some bars might also receive a layer of coating or plating to help protect against surface corrosion during storage and shipping.

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Monel 401 Plate/Pipe/Bar Chemical Composition

Monel 401 is known for its unique composition that resists the corrosive effects of rapidly moving seawater. It's often used in marine applications, but information about its exact chemical composition are restricted and not publicly available.

Monel 401 Chemical Composition

However, we can make an educated guess based on the compositions of Monel 400 and other common Monel alloys:

Nickel (Ni): 63% (minimum)

Copper (Cu): 28-34%

Iron (Fe): 2.5% max

Manganese (Mn): 2% max

Carbon (C): 0.3% max

Monel 401 Applications

Monel 401 is designed for a specific range of applications that require a specific electrical resistance and a smooth surface finish.

Common Applications include:

Paddles for seawater applications

Meter and valve parts

Electrical and electronic components

Equipment used in wire-wrapped drilling applications

Oil well tooling and marine propeller shafts

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31; | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Series: | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20; | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Product Characteristics | 1.According to the preparation process can be divided into deformation superalloys, casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| Packaging | 1. cases packed in wooden cases 2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

| Delivery | Within 7-15 days |

| Payment | L/C, T/T (30% deposit) |

Common forms of Monel bars

Monel bars are available in a variety of shapes and forms. Here are the common forms:

Round Bars: These are solid, cylindrical bars that are often used in machining and tooling applications or for products that require things like shafts, pins, or rods.

Square Bars: Square bars are solid bars with a square cross-section. They can be used in fabrications, in machine parts, or in structures.

Flat Bars: Flat bars feature a flat, rectangular cross-section. They are commonly used in construction for building frameworks or in manufacturing machinery parts due to their excellent strength-to-weight ratio.

Hexagonal Bars: Hex bars are another form that provides strength and excellent machinability. They are commonly used in nuts, bolts, fasteners, sprockets, and other such applications where the additional facets are useful.

Rectangular Bars: These are similar to flat bars but have a squarer or more substantial rectangular cross-section. They are often used in structural applications.

The choice among these forms largely depends on the specific application and requirements, including the kind of processing needed (such as cutting, drilling, welding), and the expected loads and stresses.

Monel bars offer a range of advantages due to the inherent properties of the Monel 400 alloy. Here are some of them:

Corrosion Resistance: Monel bars are highly resistant to corrosion, making them suitable for use in highly corrosive environments, such as oil and gas production, marine environments and chemical processing facilities.

High Strength: Monel bars possess good strength and toughness over a wide temperature range, making them suitable for applications that require high strength, such as fasteners and springs.

Excellent Weldability: Monel is readily weldable by most standard processes, which means that Monel bars can easily be shaped into complex structures as needed.

Thermal Stability: Monel bars have good thermal stability; they retain much of their strength at high temperatures, which makes them suitable for use in applications with high thermal demands.

Mechanical Properties: The alloy can be fully used at very low temperatures without a loss of mechanical properties. This makes it suitable for cryogenic applications.

Versatility: Because Monel bars can be obtained in a variety of shapes – rounds, squares, flats, hexagonals – they are versatile materials that can be used in a wide variety of applications.

Long-Lasting: Due to their inherent corrosion resistance and strength, products made from Monel alloy often have a longer lifespan than equivalent products made from less resistant materials.

However, the use of Monel 400, like any material, should be carefully matched to the application, environment, and required properties. Monel 400 is also generally more expensive than standard stainless steel or other common materials, and this cost factor should be taken into account in any decision to use it.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.