crystal@jsjhhsteel.com +8613327905558 102 Bldg A, 7# nongshi Rd, DongbeiTang,Xishan Dist, Wuxi,Jiangsu,CHINA

English

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

chemical composition

| % | C | Cr | Nor | Mo | Fe | B | S | Mn | Yes | P | With | Ti | To the | In |

| Min | - | 13.5 | 24.0 | 1.0 | - | 0.001 | - | - | - | - | - | 1.75 | - | - |

| Max | 0.08 | 16.0 | 27.0 | 1.5 | Allowance | 0.01 | 0.03 | 2.0 | 1.0 | 0.03 | 0.25 | 2.35 | 0.4 | 0.5 |

Physical properties

| variety | heat treatment | Temperature 0/°C | Tensile strength Σb\MPa ≥ | Elongation A/% ≥ | Section shrinkage Z/%≥ |

| Hot Sticks | Standard heat treatment | 20 | ≥895 | ≥20 | ≥40 |

| 650 | ≥735 | ≥15 | ≥20 |

Corresponding grades

| A new name for high temperatures | High Temperature Former Name | A new name for corrosion resistance | Corrosion-resistant old name | National standard grade |

| GH2132 | GH132 | x6nicrtimovb25-15-2 | ||

| Japan JIS | American Standard ASTM | American Standard UNS, SAE | German standard DIN | European EN |

| S66286,660 | incoloy A286 | 1.4980,1.4944,x5nicrti26-15 |

Fields of application

GH2132 is a Fe-Ni-Cr based precipitation hardening deformed superalloy, the use temperature range is -253 °C ~ 650 °C, in order to improve the strength, further improve the purity of the alloy, reduce the content of sulfur, gas and trace elements, and adjust the heat treatment system, with good high and low temperature strength and long-term stability, good corrosion resistance and heat deformation performance, and has good processing plasticity and satisfactory welding performance, suitable for manufacturing high-temperature load-bearing parts of aero engines working for a long time below 650 °C, Such as press discs, rotor blades and fasteners. The alloy can produce deformed products of various shapes, such as coils, forgings, plates, rods, wires and rings.

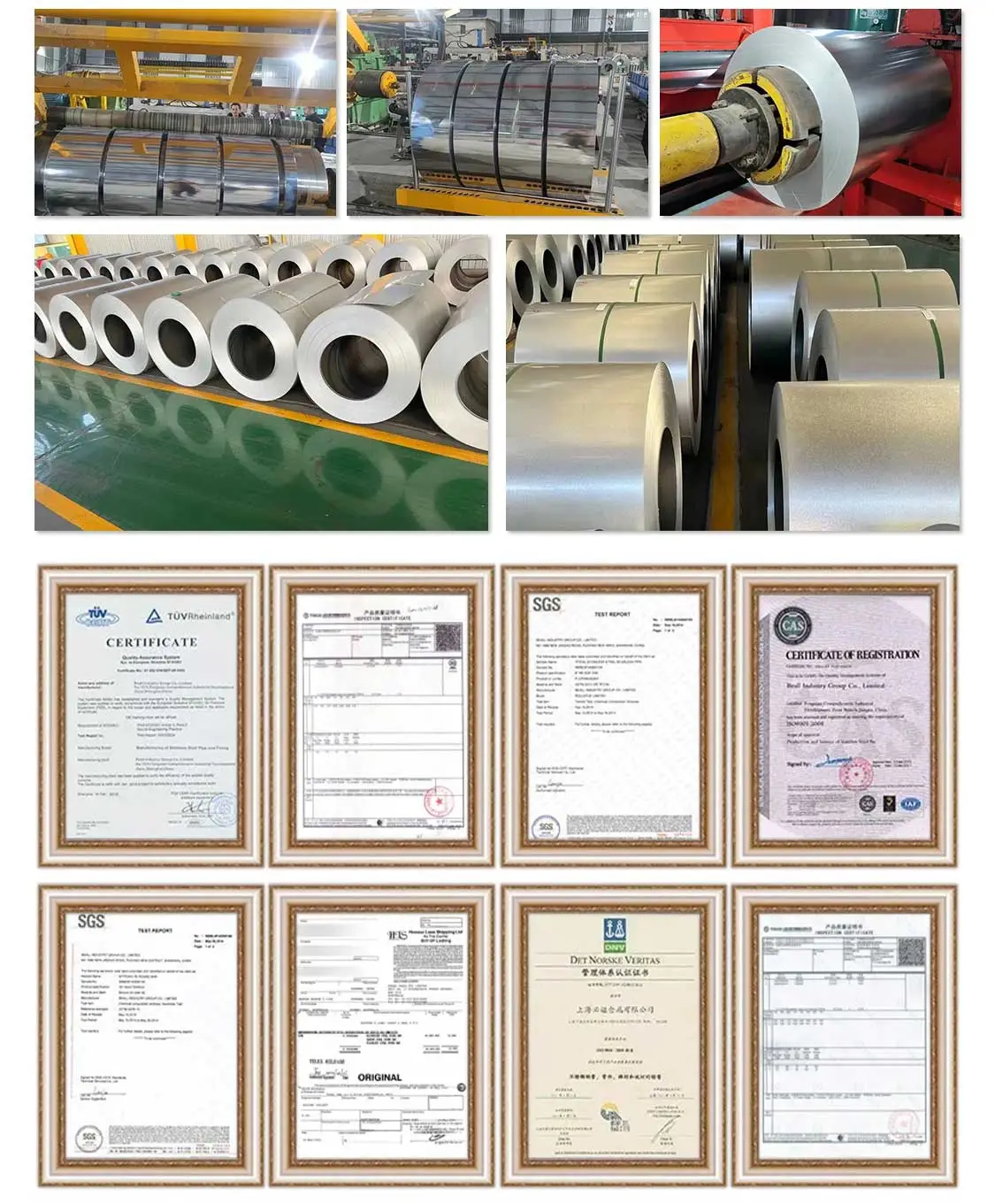

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.

chemical composition

| % | C | Cr | Nor | Mo | Fe | B | S | Mn | Yes | P | With | Ti | To the | In |

| Min | - | 13.5 | 24.0 | 1.0 | - | 0.001 | - | - | - | - | - | 1.75 | - | - |

| Max | 0.08 | 16.0 | 27.0 | 1.5 | Allowance | 0.01 | 0.03 | 2.0 | 1.0 | 0.03 | 0.25 | 2.35 | 0.4 | 0.5 |

Physical properties

| variety | heat treatment | Temperature 0/°C | Tensile strength Σb\MPa ≥ | Elongation A/% ≥ | Section shrinkage Z/%≥ |

| Hot Sticks | Standard heat treatment | 20 | ≥895 | ≥20 | ≥40 |

| 650 | ≥735 | ≥15 | ≥20 |

Corresponding grades

| A new name for high temperatures | High Temperature Former Name | A new name for corrosion resistance | Corrosion-resistant old name | National standard grade |

| GH2132 | GH132 | x6nicrtimovb25-15-2 | ||

| Japan JIS | American Standard ASTM | American Standard UNS, SAE | German standard DIN | European EN |

| S66286,660 | incoloy A286 | 1.4980,1.4944,x5nicrti26-15 |

Fields of application

GH2132 is a Fe-Ni-Cr based precipitation hardening deformed superalloy, the use temperature range is -253 °C ~ 650 °C, in order to improve the strength, further improve the purity of the alloy, reduce the content of sulfur, gas and trace elements, and adjust the heat treatment system, with good high and low temperature strength and long-term stability, good corrosion resistance and heat deformation performance, and has good processing plasticity and satisfactory welding performance, suitable for manufacturing high-temperature load-bearing parts of aero engines working for a long time below 650 °C, Such as press discs, rotor blades and fasteners. The alloy can produce deformed products of various shapes, such as coils, forgings, plates, rods, wires and rings.

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.