crystal@jsjhhsteel.com +8613327905558 102 Bldg A, 7# nongshi Rd, DongbeiTang,Xishan Dist, Wuxi,Jiangsu,CHINA

English

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

Hastelloy C-22 Plate/Pipe/Bar

Hastelloy pipe is a type of piping made from a superalloy known as Hastelloy, which belongs to the family of nickel-based alloys. It's valued for its exceptional resistance to severe forms of corrosion and high-temperature environments, making it an excellent material for harsh or demanding applications.

Hastelloy is composed of nickel, molybdenum, and chromium, with smaller amounts of other elements such as iron, tungsten, cobalt, and copper. The specific composition varies depending on the exact grade of Hastelloy being used, each one having unique properties that make it suitable for certain applications.

Metal supplier,stockist and manufacturer

We offer an extensive product line including various alloys, stainless steel, carbon steel and copper. Our alloy product portfolio includes alloy steels, aluminum alloys, nickel-based alloys, and more. Our stainless steel and carbon steel products are available in different grades and sizes to meet different industry needs. We also offer copper in various forms including sheet, bar, tube and custom shapes.

Professional service team

Our service team is the backbone of the customer relationship, ensuring every interaction with our company is seamless, informative and satisfying. With a customer-centric approach, our professionals provide end-to-end support, from handling queries to after-sales services, ensuring your complete satisfaction at every step.

Expert technical team

Our company's technical prowess is unparalleled. Our team of engineers and technicians bring years of experience and a passion for innovation to produce metal with precision and care. Their expertise ensures our products can withstand the rigorous demands of any application, delivering reliability and performance.

here's an expanded table with eight common Hastelloy Bar models and their applications.

These are simplified descriptions of each model and their usual applications. The actual use cases can vary based on requirements, and there may be other Hastelloy alloys more suitable for specific industrial needs.

here's that information in a table format.

| Hastelloy C-22 Plate/Pipe/Bar Model | Common Applications |

|---|---|

| Hastelloy C276 | Chemical process and waste treatment, pollution control, pulp and paper production, and recovery of sour natural gas. |

| Hastelloy C22 | Chemical processing, waste treatment, pulp and paper production, production of chlorinated plastics, and marine environments. |

| Hastelloy B2 | Chemical processing (especially in reactions generating non-oxidizing acids), pure and contaminant wastewater management industries. |

| Hastelloy C2000 | Chemical processing, pollution control, and waste treatment facilities dealing with mixed acid solutions and oxidizing effects. |

| Hastelloy X | Gas turbine engine components, heat-treating equipment, and industrial furnace structural parts. |

| Hastelloy B3 | Chemical processing applications particularly under reducing conditions in sulfuric and hydrochloric acid mediums. |

| Hastelloy G30 | Applications involving sulfuric, phosphoric, and nitric acids in the chemical processing industry. |

| Hastelloy N | Nuclear fuel reprocessing plants and molten salt reactor systems due to its high-temperature resistance in nuclear reactors. |

Hastelloy pipe production process

The production process of Hastelloy pipes involves several steps that ensure the pipes' durability, corrosion resistance, and overall high performance. Here is a general overview of the process:

Raw Materials: The process begins with raw materials. The primary alloying elements for Hastelloy include nickel, molybdenum, chromium, and iron, but the specific composition depends on the Hastelloy grade.

Melting: The raw materials are placed into an electric furnace and melted at temperatures often exceeding 1200°C. Some grades may also include an electroslag remelting process for enhanced uniformity and cleanliness.

Removal of Impurities: The melted alloy is then processed to remove impurities. This typically involves ladle refining, where adjustments can also be made to the alloy composition.

Casting: The refined, molten alloy is then cast into large, semi-finished shapes such as ingots, billets, or slabs.

Hot and Cold Working: The cast alloy undergoes hot working (at high temperatures), typically through processes such as forging or rolling. After the hot working processes, the alloy undergoes cold working (at or near room temperature). This could be further rolling or drawing to decrease the cross-sectional area, increase hardness, and improve surface finish.

Heat Treatment: A heat treatment process is then implemented to fine-tune the alloy's microstructure for its specific mechanical properties. This can include solution annealing, quenching, and aging.

Pipe Forming: The treated materials are then formed into pipes using methods such as extrusion or rotary piercing for seamless pipes, or bending and welding for welded pipes.

Finishing: Depending on the end use of the pipe, it may undergo different finishing processes. This can include cutting the pipe to length, treating the ends, or surface finishing to ensure a smooth pipe wall. Some pipes may have an additional heat treatment at this stage.

Inspection and Testing: The final step involves inspections and testing to make sure the pipe meets all necessary quality and performance standards. This usually includes checks for dimensional accuracy and surface quality, as well as mechanical testing, non-destructive testing, and corrosion resistance testing.

Throughout these steps, the process needs to be monitored and controlled closely to ensure the pipe meets the specific requirements for the Hastelloy grade. The manufacturing process will vary slightly between different Hastelloy grades and based on the specific applications the pipe will be used for.

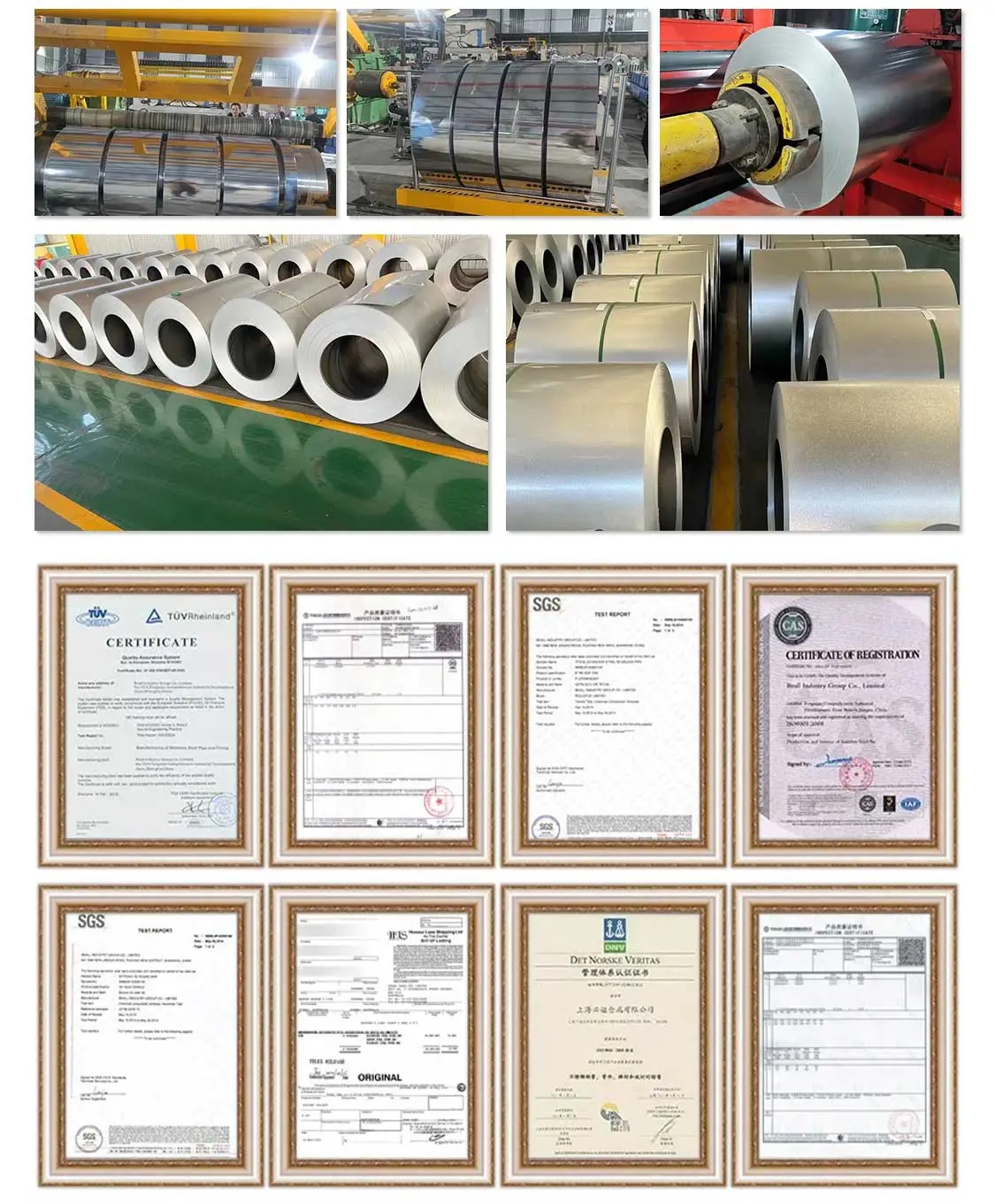

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Hastelloy C-22 Pipe Chemical Composition

Hastelloy C-22 is a nickel-chromium-molybdenum alloy with enhanced resistance to pitting, crevice corrosion, and stress corrosion cracking.

Here's the typical chemical composition of Hastelloy C-22:

Nickel (Ni): Balance

Chromium (Cr): 20.0-22.5%

Molybdenum (Mo): 12.5-14.5%

Iron (Fe): ≤6.0%

Tungsten (W): 2.5-3.5%

Cobalt (Co): ≤2.5%

Carbon (C): ≤0.015%

Silicon (Si): ≤0.08%

Manganese (Mn): ≤0.50%

Vanadium (V): ≤0.35%

Phosphorous (P): ≤0.025%

Sulfur (S): ≤0.02%

Note: The above composition is an approximation, and exact specifications may vary based on requirements.

Common Applications

Common applications of Hastelloy C-22 are typically found in environments that require excellent resistance to corrosion. These include:

Chemical processing industry: Hastelloy C-22 is widely used in the chemical processing industry due to its high resistance to multiple chemicals at high temperatures. This includes applications in reactors, heat exchangers, and columns.

Pollution control: Hastelloy C-22 is good for applications that are designed to control pollution. It can resist the harmful effects of chemicals that are used to reduce pollution.

Waste Treatment: C-22 is often utilized in waste treatment plants, especially those dealing with industrial waste, due to its corrosion resistance.

Pharmaceutical industry: The alloy is used for various components, as its qualities make it safe and reliable for the high-sanitation levels necessary for drug creation and biotechnology.

Pulp and paper industry: Hastelloy C-22's resistance to chlorine dioxide, a chemical heavily used in the paper industry, makes it an ideal material for this industry.

Energy industry: Hastelloy C-22 may also be found in power plants and energy-related facilities that use sulfuric, phosphoric, or nitric acids, given its excellent resistance against these chemicals

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31; | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Series: | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20; | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Product Characteristics | 1.According to the preparation process can be divided into deformation superalloys, casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| Packaging | 1. cases packed in wooden cases 2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

| Delivery | Within 7-15 days |

| Payment | L/C, T/T (30% deposit) |

Common forms of Hastelloy pipe

Hastelloy pipes are available in various forms to cater to the specific requirements of different applications. The most common forms are:

Seamless Pipes: These are pipes that are manufactured from a solid round billet which is heated and pushed over a form until the Hastelloy is shaped into a hollow tube. Seamless pipes are typically used in applications where the high pressure, high temperature, or high mechanical stress requires robust performance, typically in process industries.

Welded Pipes: These pipes are manufactured from a plate or sheet which is rolled into the desired shape. The edges are then heated and fused together using a variety of welding techniques. Welded pipes are typically used in applications where the pressure is not as high, and where the pipe shape or size requires a larger diameter or non-standard dimensions.

Round Pipes: This is the most common form of Hastelloy pipe, used in a wide variety of applications where circular cross-section is adequate for the fluid or gas flowing through it.

Square and Rectangular Tubes: While not as common as round pipes, Hastelloy is sometimes formed into square or rectangular tubes for specific applications that need these shapes.

Hastelloy Pipe Fittings: Apart from the pipes themselves, Hastelloy is also used to manufacture various pipe fittings such as elbows, tees, flanges, and reducers to join pipes together in a piping system.

Hastelloy pipes, particularly those made of grades like C276, offer multiple advantages for use in a wide variety of industries, especially those requiring strong resistance to heat, pressure, and corrosion. Here are some key advantages:

Corrosion Resistance: Hastelloy pipes are renowned for superb corrosion resistance, even in extreme conditions. They can resist a wide variety of corrosive environments, including strong oxidizers, hot contaminated media, chlorine, formic and acetic acids, acetic anhydride, seawater, and brine solutions.

Heat Resistance: Hastelloy pipes can withstand high temperatures while maintaining a high degree of formability and weldability. This makes them appropriate for many high-heat applications such as heat exchangers or chemical processing.

Mechanical Strength: Hastelloy pipes provide superior tensile strength, even when faced with high temperatures or increased pressure. This makes them particularly reliable in tough conditions.

Versatility: Hastelloy can be formed and welded into various shapes and sizes, making it highly versatile for different applications. Whether the application requires seamless, welded, round, or square pipes, Hastelloy can cater to these needs.

Longevity: Despite the higher cost compared to other materials, Hastelloy pipes tend to have a longer lifespan due to their superior durability. This can lead to lower operational costs over time as replacements are needed less frequently.

Stress Corrosion Cracking Resistance: Hastelloy C276, for instance, is resistant to stress corrosion cracking and pitting. These types of corrosion damage can lead to catastrophic failure in normal steels and even some stainless steels, but Hastelloy is designed to resist this type of damage.

Hastelloy's benefits contribute to its widespread use in industries such as oil and gas, chemical processing, power generation, pharmaceuticals, and more. However, due to material cost and machining requirements, it's often deployed in those environments where its unique properties can add the most value.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.

Hastelloy C-22 Plate/Pipe/Bar

Hastelloy pipe is a type of piping made from a superalloy known as Hastelloy, which belongs to the family of nickel-based alloys. It's valued for its exceptional resistance to severe forms of corrosion and high-temperature environments, making it an excellent material for harsh or demanding applications.

Hastelloy is composed of nickel, molybdenum, and chromium, with smaller amounts of other elements such as iron, tungsten, cobalt, and copper. The specific composition varies depending on the exact grade of Hastelloy being used, each one having unique properties that make it suitable for certain applications.

Metal supplier,stockist and manufacturer

We offer an extensive product line including various alloys, stainless steel, carbon steel and copper. Our alloy product portfolio includes alloy steels, aluminum alloys, nickel-based alloys, and more. Our stainless steel and carbon steel products are available in different grades and sizes to meet different industry needs. We also offer copper in various forms including sheet, bar, tube and custom shapes.

Professional service team

Our service team is the backbone of the customer relationship, ensuring every interaction with our company is seamless, informative and satisfying. With a customer-centric approach, our professionals provide end-to-end support, from handling queries to after-sales services, ensuring your complete satisfaction at every step.

Expert technical team

Our company's technical prowess is unparalleled. Our team of engineers and technicians bring years of experience and a passion for innovation to produce metal with precision and care. Their expertise ensures our products can withstand the rigorous demands of any application, delivering reliability and performance.

here's an expanded table with eight common Hastelloy Bar models and their applications.

These are simplified descriptions of each model and their usual applications. The actual use cases can vary based on requirements, and there may be other Hastelloy alloys more suitable for specific industrial needs.

here's that information in a table format.

| Hastelloy C-22 Plate/Pipe/Bar Model | Common Applications |

|---|---|

| Hastelloy C276 | Chemical process and waste treatment, pollution control, pulp and paper production, and recovery of sour natural gas. |

| Hastelloy C22 | Chemical processing, waste treatment, pulp and paper production, production of chlorinated plastics, and marine environments. |

| Hastelloy B2 | Chemical processing (especially in reactions generating non-oxidizing acids), pure and contaminant wastewater management industries. |

| Hastelloy C2000 | Chemical processing, pollution control, and waste treatment facilities dealing with mixed acid solutions and oxidizing effects. |

| Hastelloy X | Gas turbine engine components, heat-treating equipment, and industrial furnace structural parts. |

| Hastelloy B3 | Chemical processing applications particularly under reducing conditions in sulfuric and hydrochloric acid mediums. |

| Hastelloy G30 | Applications involving sulfuric, phosphoric, and nitric acids in the chemical processing industry. |

| Hastelloy N | Nuclear fuel reprocessing plants and molten salt reactor systems due to its high-temperature resistance in nuclear reactors. |

Hastelloy pipe production process

The production process of Hastelloy pipes involves several steps that ensure the pipes' durability, corrosion resistance, and overall high performance. Here is a general overview of the process:

Raw Materials: The process begins with raw materials. The primary alloying elements for Hastelloy include nickel, molybdenum, chromium, and iron, but the specific composition depends on the Hastelloy grade.

Melting: The raw materials are placed into an electric furnace and melted at temperatures often exceeding 1200°C. Some grades may also include an electroslag remelting process for enhanced uniformity and cleanliness.

Removal of Impurities: The melted alloy is then processed to remove impurities. This typically involves ladle refining, where adjustments can also be made to the alloy composition.

Casting: The refined, molten alloy is then cast into large, semi-finished shapes such as ingots, billets, or slabs.

Hot and Cold Working: The cast alloy undergoes hot working (at high temperatures), typically through processes such as forging or rolling. After the hot working processes, the alloy undergoes cold working (at or near room temperature). This could be further rolling or drawing to decrease the cross-sectional area, increase hardness, and improve surface finish.

Heat Treatment: A heat treatment process is then implemented to fine-tune the alloy's microstructure for its specific mechanical properties. This can include solution annealing, quenching, and aging.

Pipe Forming: The treated materials are then formed into pipes using methods such as extrusion or rotary piercing for seamless pipes, or bending and welding for welded pipes.

Finishing: Depending on the end use of the pipe, it may undergo different finishing processes. This can include cutting the pipe to length, treating the ends, or surface finishing to ensure a smooth pipe wall. Some pipes may have an additional heat treatment at this stage.

Inspection and Testing: The final step involves inspections and testing to make sure the pipe meets all necessary quality and performance standards. This usually includes checks for dimensional accuracy and surface quality, as well as mechanical testing, non-destructive testing, and corrosion resistance testing.

Throughout these steps, the process needs to be monitored and controlled closely to ensure the pipe meets the specific requirements for the Hastelloy grade. The manufacturing process will vary slightly between different Hastelloy grades and based on the specific applications the pipe will be used for.

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Hastelloy C-22 Pipe Chemical Composition

Hastelloy C-22 is a nickel-chromium-molybdenum alloy with enhanced resistance to pitting, crevice corrosion, and stress corrosion cracking.

Here's the typical chemical composition of Hastelloy C-22:

Nickel (Ni): Balance

Chromium (Cr): 20.0-22.5%

Molybdenum (Mo): 12.5-14.5%

Iron (Fe): ≤6.0%

Tungsten (W): 2.5-3.5%

Cobalt (Co): ≤2.5%

Carbon (C): ≤0.015%

Silicon (Si): ≤0.08%

Manganese (Mn): ≤0.50%

Vanadium (V): ≤0.35%

Phosphorous (P): ≤0.025%

Sulfur (S): ≤0.02%

Note: The above composition is an approximation, and exact specifications may vary based on requirements.

Common Applications

Common applications of Hastelloy C-22 are typically found in environments that require excellent resistance to corrosion. These include:

Chemical processing industry: Hastelloy C-22 is widely used in the chemical processing industry due to its high resistance to multiple chemicals at high temperatures. This includes applications in reactors, heat exchangers, and columns.

Pollution control: Hastelloy C-22 is good for applications that are designed to control pollution. It can resist the harmful effects of chemicals that are used to reduce pollution.

Waste Treatment: C-22 is often utilized in waste treatment plants, especially those dealing with industrial waste, due to its corrosion resistance.

Pharmaceutical industry: The alloy is used for various components, as its qualities make it safe and reliable for the high-sanitation levels necessary for drug creation and biotechnology.

Pulp and paper industry: Hastelloy C-22's resistance to chlorine dioxide, a chemical heavily used in the paper industry, makes it an ideal material for this industry.

Energy industry: Hastelloy C-22 may also be found in power plants and energy-related facilities that use sulfuric, phosphoric, or nitric acids, given its excellent resistance against these chemicals

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31; | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Series: | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20; | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Product Characteristics | 1.According to the preparation process can be divided into deformation superalloys, casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| Packaging | 1. cases packed in wooden cases 2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

| Delivery | Within 7-15 days |

| Payment | L/C, T/T (30% deposit) |

Common forms of Hastelloy pipe

Hastelloy pipes are available in various forms to cater to the specific requirements of different applications. The most common forms are:

Seamless Pipes: These are pipes that are manufactured from a solid round billet which is heated and pushed over a form until the Hastelloy is shaped into a hollow tube. Seamless pipes are typically used in applications where the high pressure, high temperature, or high mechanical stress requires robust performance, typically in process industries.

Welded Pipes: These pipes are manufactured from a plate or sheet which is rolled into the desired shape. The edges are then heated and fused together using a variety of welding techniques. Welded pipes are typically used in applications where the pressure is not as high, and where the pipe shape or size requires a larger diameter or non-standard dimensions.

Round Pipes: This is the most common form of Hastelloy pipe, used in a wide variety of applications where circular cross-section is adequate for the fluid or gas flowing through it.

Square and Rectangular Tubes: While not as common as round pipes, Hastelloy is sometimes formed into square or rectangular tubes for specific applications that need these shapes.

Hastelloy Pipe Fittings: Apart from the pipes themselves, Hastelloy is also used to manufacture various pipe fittings such as elbows, tees, flanges, and reducers to join pipes together in a piping system.

Hastelloy pipes, particularly those made of grades like C276, offer multiple advantages for use in a wide variety of industries, especially those requiring strong resistance to heat, pressure, and corrosion. Here are some key advantages:

Corrosion Resistance: Hastelloy pipes are renowned for superb corrosion resistance, even in extreme conditions. They can resist a wide variety of corrosive environments, including strong oxidizers, hot contaminated media, chlorine, formic and acetic acids, acetic anhydride, seawater, and brine solutions.

Heat Resistance: Hastelloy pipes can withstand high temperatures while maintaining a high degree of formability and weldability. This makes them appropriate for many high-heat applications such as heat exchangers or chemical processing.

Mechanical Strength: Hastelloy pipes provide superior tensile strength, even when faced with high temperatures or increased pressure. This makes them particularly reliable in tough conditions.

Versatility: Hastelloy can be formed and welded into various shapes and sizes, making it highly versatile for different applications. Whether the application requires seamless, welded, round, or square pipes, Hastelloy can cater to these needs.

Longevity: Despite the higher cost compared to other materials, Hastelloy pipes tend to have a longer lifespan due to their superior durability. This can lead to lower operational costs over time as replacements are needed less frequently.

Stress Corrosion Cracking Resistance: Hastelloy C276, for instance, is resistant to stress corrosion cracking and pitting. These types of corrosion damage can lead to catastrophic failure in normal steels and even some stainless steels, but Hastelloy is designed to resist this type of damage.

Hastelloy's benefits contribute to its widespread use in industries such as oil and gas, chemical processing, power generation, pharmaceuticals, and more. However, due to material cost and machining requirements, it's often deployed in those environments where its unique properties can add the most value.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.