crystal@jsjhhsteel.com +8613327905558 102 Bldg A, 7# nongshi Rd, DongbeiTang,Xishan Dist, Wuxi,Jiangsu,CHINA

English

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

gh3030(gh30)

The alloy is an early development of 80Ni-20Cr solution-strengthened superalloy, with simple chemical composition, satisfactory thermal strength and high plasticity below 800 °C, and good oxidation resistance, thermal fatigue, cold stamping and welding process performance. The alloy is single-phase austenite after solution treatment, and the structure is stable during use. It is mainly used for turbine engine combustion chamber parts that work below 800°C and other high-temperature parts that require oxidation resistance below 1100°C but bear little load.

Metallographic organizational structure

The alloy is a single-phase austenite structure with a small amount of TiC and Ti(CN) between the solid solution treatment at 1000 degrees Celsius.

Process performance

1. The alloy has good malleability, with a forging heating temperature of 1180 °C and a final forging of 900 °C.

2. The average grain size of the alloy is closely related to the deformation degree of the forging and the final forging temperature.

3. After heat treatment, the oxide scale on the surface of the parts can be removed by sand blowing or pickling.

Melting and casting processes

Electric arc furnace melting or electric arc furnace melting plus electroslag remelting or vacuum arc remelting, non-vacuum induction furnace plus electroslag melting or vacuum electric arc furnace remelting or vacuum duplex process.

Application overview and special requirements

The alloy has been tested in aero engines for a long time, and is mainly used for combustion chamber and afterburner parts, as well as casing mounting edges.

Product parameters

chemical composition

C | Cr | Ni | Ti | Al | Fe | Mn | Si | P | S |

≤0.12 | 19.0~22.0 | Allowance | 0.15~0.35 | ≤0.15 | ≤1.5 | ≤0.7 | ≤0.8 | ≤0.03 | ≤0.02 |

Note: 1. The standard for bars and ring blanks stipulates that Cu ≤ 0.20%.

2. The standard of hot-rolled plate, cold-rolled plate, cold-rolled strip, pipe, wire and cold-drawn wire for cold heading stipulates that Fe ≤ 1.00%, P≤0.015%, S≤0.010%, Pb≤0.001%, Cu≤0.007%.

GH3030 Physical Properties:

| Density g/cm3 | Melting point | Thermal conductivity | Specific heat capacity | Modulus of elasticity | Shear modulus | Resistivity | Poisson's ratio | Linear expansion coefficient |

8.4 | 1374 1420 | 15.1(100℃) | 565.2 | 224 | 1.09 | 12.8(20~100℃) |

main grades:

Hastelloy C276, Hastelloy B2/B3, 904L, 254smo, S30815, 2205, 2507, S32760, Incoloy800, Incoloy825, Inconel600, Inconel601, Inconel625, Inconel718, HastelloyC-2000, Hastelloy, HastelloyX, Monel400,GH2132,GH3030,GH3039,GH4169,GH4145, NS333,NS334,NS335,NS336,Alloy20,Alloy59,Alloy 926,N08367,N08926。

Product specifications can be provided including round bar, round bar, rod, plate, seamless pipe, wire, fasteners, flanges, pipe fittings, steel strips, forgings, flanges, welded pipes, cold wire drawing, steel strips, welding consumables, etc., which are widely used in petrochemical, aerospace, pharmaceutical papermaking, food industry, electric power ships, marine transportation, and many other fields, all products are strictly in accordance with GB (NATIONAL STANDARD), ASTM/ASME (American Standard), JIS (Japanese standard) and other standard production testing.

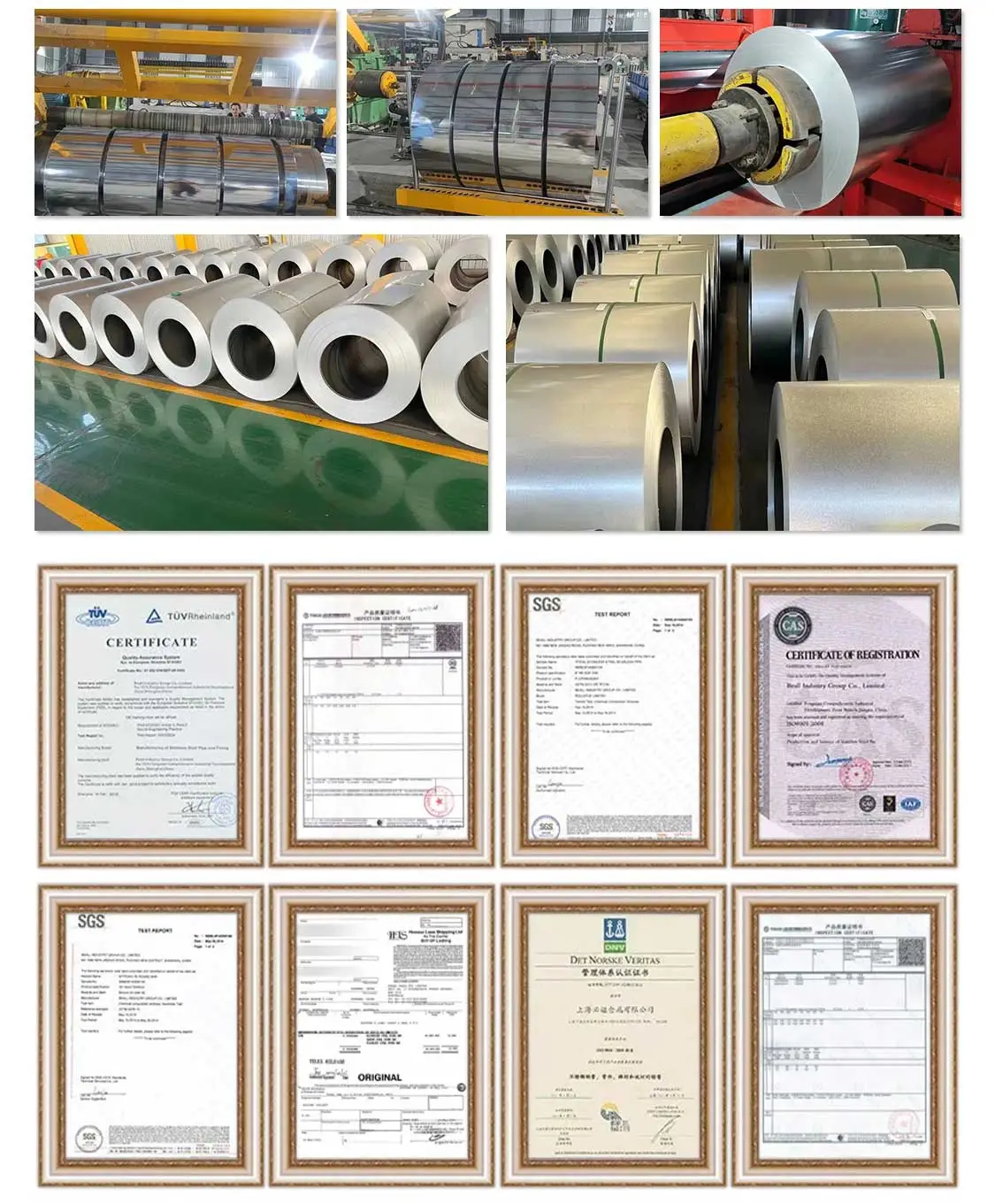

Our advantage

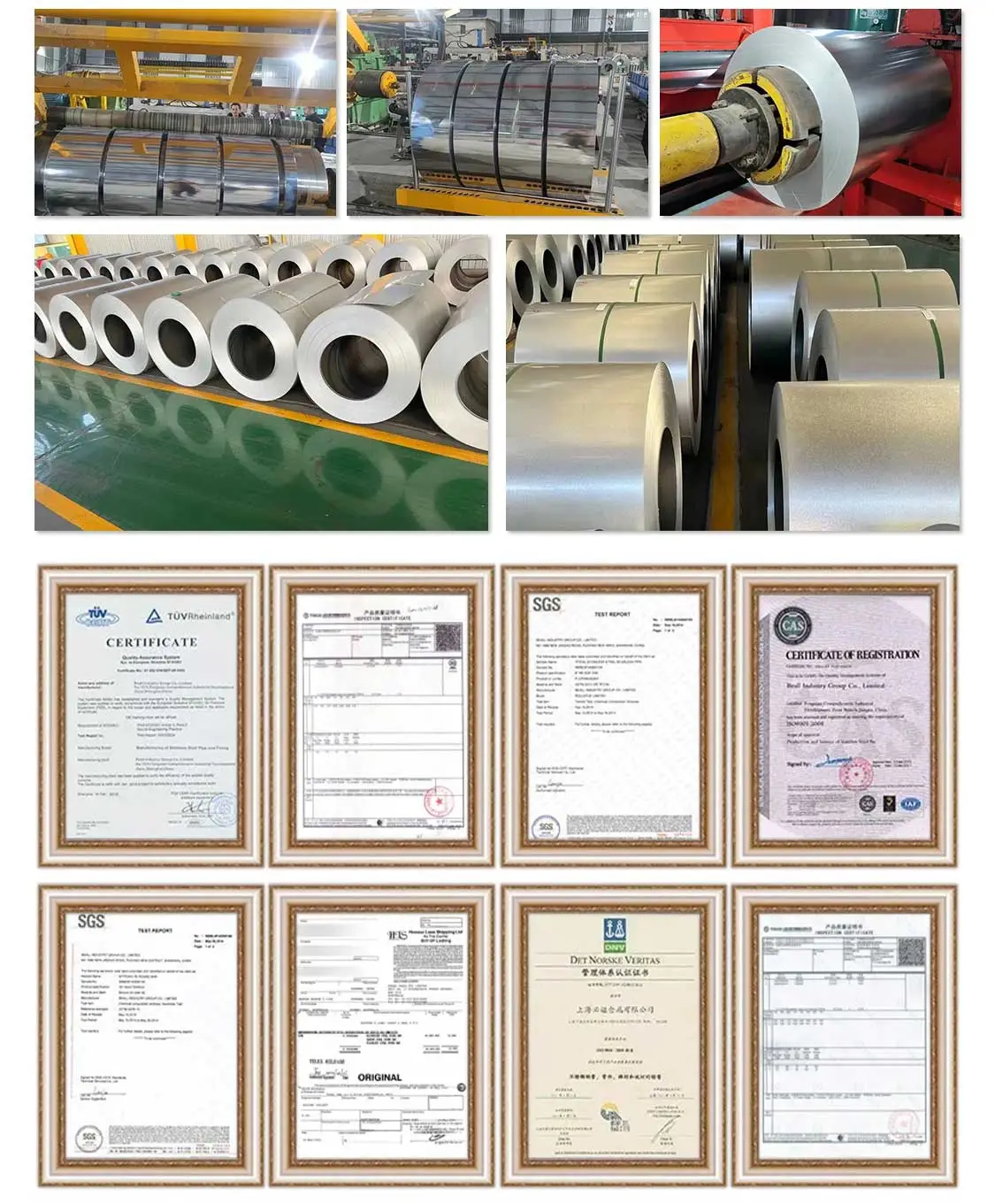

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.

gh3030(gh30)

The alloy is an early development of 80Ni-20Cr solution-strengthened superalloy, with simple chemical composition, satisfactory thermal strength and high plasticity below 800 °C, and good oxidation resistance, thermal fatigue, cold stamping and welding process performance. The alloy is single-phase austenite after solution treatment, and the structure is stable during use. It is mainly used for turbine engine combustion chamber parts that work below 800°C and other high-temperature parts that require oxidation resistance below 1100°C but bear little load.

Metallographic organizational structure

The alloy is a single-phase austenite structure with a small amount of TiC and Ti(CN) between the solid solution treatment at 1000 degrees Celsius.

Process performance

1. The alloy has good malleability, with a forging heating temperature of 1180 °C and a final forging of 900 °C.

2. The average grain size of the alloy is closely related to the deformation degree of the forging and the final forging temperature.

3. After heat treatment, the oxide scale on the surface of the parts can be removed by sand blowing or pickling.

Melting and casting processes

Electric arc furnace melting or electric arc furnace melting plus electroslag remelting or vacuum arc remelting, non-vacuum induction furnace plus electroslag melting or vacuum electric arc furnace remelting or vacuum duplex process.

Application overview and special requirements

The alloy has been tested in aero engines for a long time, and is mainly used for combustion chamber and afterburner parts, as well as casing mounting edges.

Product parameters

chemical composition

C | Cr | Ni | Ti | Al | Fe | Mn | Si | P | S |

≤0.12 | 19.0~22.0 | Allowance | 0.15~0.35 | ≤0.15 | ≤1.5 | ≤0.7 | ≤0.8 | ≤0.03 | ≤0.02 |

Note: 1. The standard for bars and ring blanks stipulates that Cu ≤ 0.20%.

2. The standard of hot-rolled plate, cold-rolled plate, cold-rolled strip, pipe, wire and cold-drawn wire for cold heading stipulates that Fe ≤ 1.00%, P≤0.015%, S≤0.010%, Pb≤0.001%, Cu≤0.007%.

GH3030 Physical Properties:

| Density g/cm3 | Melting point | Thermal conductivity | Specific heat capacity | Modulus of elasticity | Shear modulus | Resistivity | Poisson's ratio | Linear expansion coefficient |

8.4 | 1374 1420 | 15.1(100℃) | 565.2 | 224 | 1.09 | 12.8(20~100℃) |

main grades:

Hastelloy C276, Hastelloy B2/B3, 904L, 254smo, S30815, 2205, 2507, S32760, Incoloy800, Incoloy825, Inconel600, Inconel601, Inconel625, Inconel718, HastelloyC-2000, Hastelloy, HastelloyX, Monel400,GH2132,GH3030,GH3039,GH4169,GH4145, NS333,NS334,NS335,NS336,Alloy20,Alloy59,Alloy 926,N08367,N08926。

Product specifications can be provided including round bar, round bar, rod, plate, seamless pipe, wire, fasteners, flanges, pipe fittings, steel strips, forgings, flanges, welded pipes, cold wire drawing, steel strips, welding consumables, etc., which are widely used in petrochemical, aerospace, pharmaceutical papermaking, food industry, electric power ships, marine transportation, and many other fields, all products are strictly in accordance with GB (NATIONAL STANDARD), ASTM/ASME (American Standard), JIS (Japanese standard) and other standard production testing.

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.