crystal@jsjhhsteel.com +8613327905558 102 Bldg A, 7# nongshi Rd, DongbeiTang,Xishan Dist, Wuxi,Jiangsu,CHINA

English

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

There are two kinds of titanium plate implementation standards, the national standard is GB/T3621-2007, GB/T13810-2007, and the American standard is ASTM B265, ASTM F136, ASTM F67, AMS4928.

trademark

US brand numbers: GR1, GR2, GR3, GR5, GR7, GR12

Russian plate number: BT1-00, BT1-0, fBT1-2, etc

Domestic grades: TA0, TA2, TA3, TA5, TA6, TA7, TA9, TA10, TB2, TC1, TC2, TC3, TC4

1. Citation standards

1.GB 228 Metal tensile test method

2. GB/T 3620.1 Titanium and titanium number and chemical composition

3. GB/T3620.2 Titanium and titanium alloy processing products chemical composition and composition allowable deviation

4. GB 4698 chemical analysis method of sponge titanium, titanium and ferroalloy

Titanium plate specifications

Grades: TA1, TA2, TA3, TC4, GR1, GR2, GR5

Standards: GB/T 3621-2007, GB/T 13810-2007ASTM B265, ASTM F136, ASTM F67,

Size: T 0.5-5.0mm x W1000mm x L 2000-3500mmT 6.0- 30mm x W1000-2500mm x L 3000-6000mmT 30- 80mm x W1000mm x L 2000mm

Uses: metallurgy, electronics, medical, chemical, petroleum, medicine, aerospace, etc.

Hot working state (R)

Cold working state (Y)

Annealed state(M)

Titanium plate manufacturing process

Hot forging: A forging process performed above the metal recrystallization temperature.

Hot rolling: A rolling process carried out at temperatures above recrystallization.

Cold rolling: A rolling process in which the plastic deformation temperature is lower than the recovery temperature.

Annealing: A metal heat treatment process in which metal is slowly heated to a certain temperature, held for sufficient time, and then cooled at an appropriate rate (usually slowly, sometimes controlled).

Pickling: The part is immersed in an aqueous solution such as sulfuric acid to remove a film such as oxide on the metal surface. It is the pre-treatment or intermediate treatment of electroplating, enamel, rolling and other processes.

Features of titanium plate

1. Titanium seed plate is the surface of the oxide film equivalent to a good wear-resistant hair separator, the use of titanium seed plate saves the separation agent, so that the plate peeling is easy, eliminating the process of pretreatment of the seed plate, titanium seed plate is half lighter than copper seed plate.

2. The service life of titanium seed plate is more than 3 times that of copper seed plate, and it can reach 10 to 20 years according to operating conditions.

3. The electrolytic copper crystal structure prepared by titanium seed plate is dense, the surface is smooth and smooth, and the quality is excellent.

4. Since the titanium seed plate does not need to be coated with separating agent, the contamination of copper electrolyte can be avoided.

5. Improve production capacity and reduce the production cost of electrolytic copper, so as to have better economic benefits.

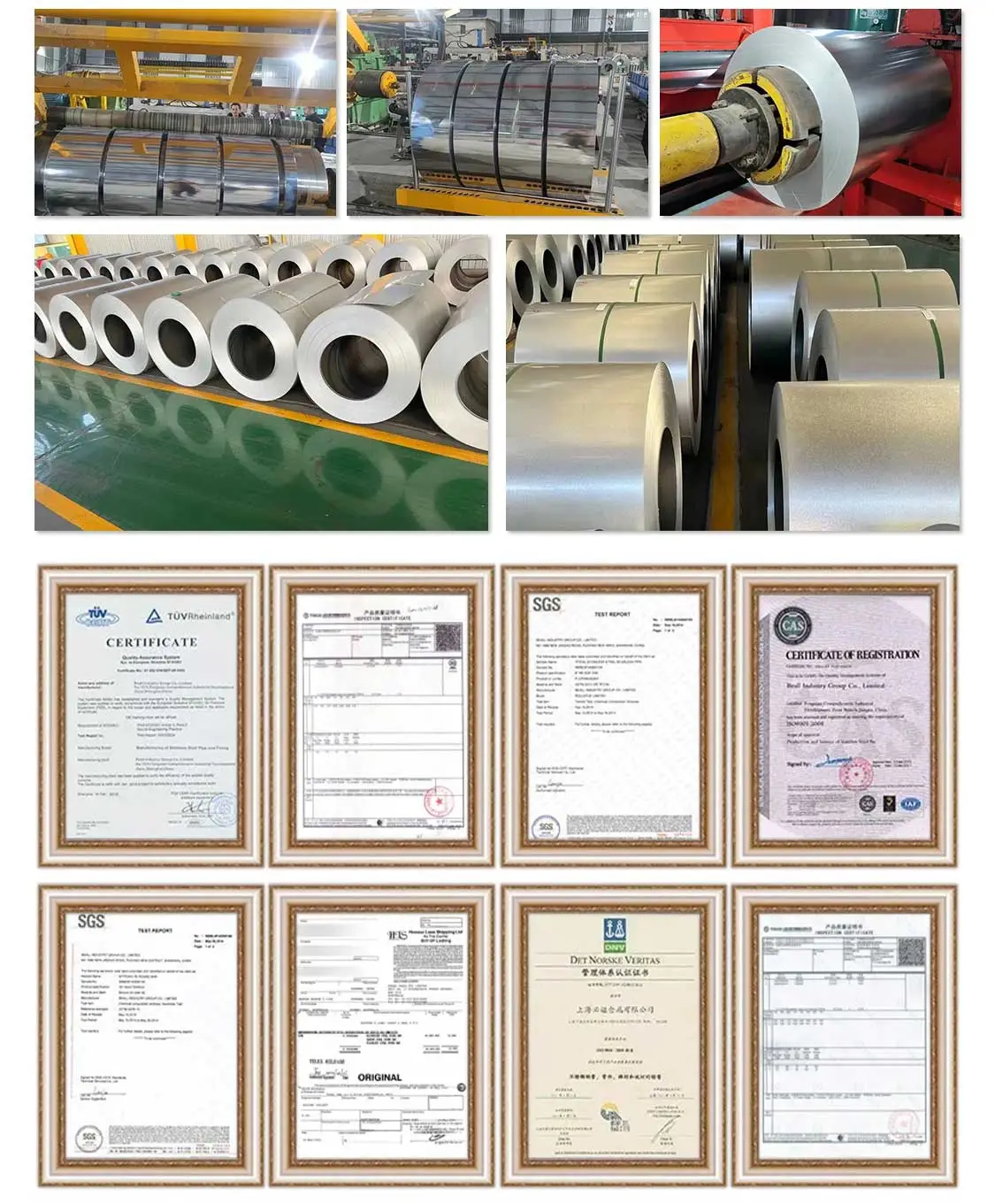

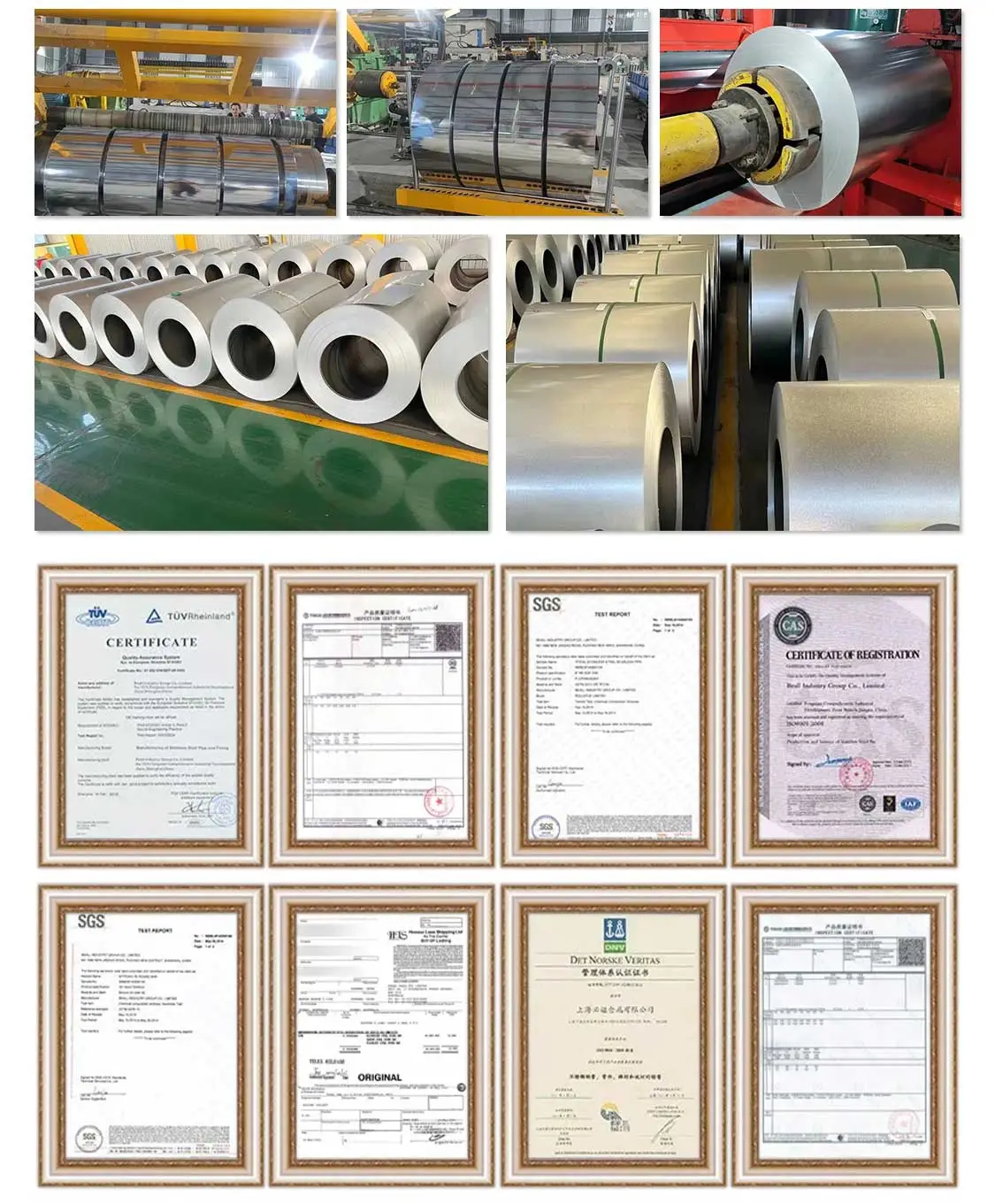

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.

There are two kinds of titanium plate implementation standards, the national standard is GB/T3621-2007, GB/T13810-2007, and the American standard is ASTM B265, ASTM F136, ASTM F67, AMS4928.

trademark

US brand numbers: GR1, GR2, GR3, GR5, GR7, GR12

Russian plate number: BT1-00, BT1-0, fBT1-2, etc

Domestic grades: TA0, TA2, TA3, TA5, TA6, TA7, TA9, TA10, TB2, TC1, TC2, TC3, TC4

1. Citation standards

1.GB 228 Metal tensile test method

2. GB/T 3620.1 Titanium and titanium number and chemical composition

3. GB/T3620.2 Titanium and titanium alloy processing products chemical composition and composition allowable deviation

4. GB 4698 chemical analysis method of sponge titanium, titanium and ferroalloy

Titanium plate specifications

Grades: TA1, TA2, TA3, TC4, GR1, GR2, GR5

Standards: GB/T 3621-2007, GB/T 13810-2007ASTM B265, ASTM F136, ASTM F67,

Size: T 0.5-5.0mm x W1000mm x L 2000-3500mmT 6.0- 30mm x W1000-2500mm x L 3000-6000mmT 30- 80mm x W1000mm x L 2000mm

Uses: metallurgy, electronics, medical, chemical, petroleum, medicine, aerospace, etc.

Hot working state (R)

Cold working state (Y)

Annealed state(M)

Titanium plate manufacturing process

Hot forging: A forging process performed above the metal recrystallization temperature.

Hot rolling: A rolling process carried out at temperatures above recrystallization.

Cold rolling: A rolling process in which the plastic deformation temperature is lower than the recovery temperature.

Annealing: A metal heat treatment process in which metal is slowly heated to a certain temperature, held for sufficient time, and then cooled at an appropriate rate (usually slowly, sometimes controlled).

Pickling: The part is immersed in an aqueous solution such as sulfuric acid to remove a film such as oxide on the metal surface. It is the pre-treatment or intermediate treatment of electroplating, enamel, rolling and other processes.

Features of titanium plate

1. Titanium seed plate is the surface of the oxide film equivalent to a good wear-resistant hair separator, the use of titanium seed plate saves the separation agent, so that the plate peeling is easy, eliminating the process of pretreatment of the seed plate, titanium seed plate is half lighter than copper seed plate.

2. The service life of titanium seed plate is more than 3 times that of copper seed plate, and it can reach 10 to 20 years according to operating conditions.

3. The electrolytic copper crystal structure prepared by titanium seed plate is dense, the surface is smooth and smooth, and the quality is excellent.

4. Since the titanium seed plate does not need to be coated with separating agent, the contamination of copper electrolyte can be avoided.

5. Improve production capacity and reduce the production cost of electrolytic copper, so as to have better economic benefits.

Our advantage

Quality Assurance: We take pride in our rigorous testing and quality control measures that ensure only the best materials reach our clients.

Advanced Technology: Our facilities are equipped with state-of-the-art technology for both standard and custom metal production.

Vast Inventory: We boast a comprehensive inventory that enables us to fulfill orders rapidly and efficiently.

Custom Fabrication: Our team of experts works closely with clients to provide bespoke solutions tailored to their specific needs.

Q: How can I pay my order?

A: We accept T/T, Western Union,Alibaba Online Payment to pay.

Q: Do you have any certificate?

A: We have passed ISO9001:2008,ISO14001OHSAS18001 and obtained CE certificate and BSCI certificate from UL.

Q: Why the model name of your machine same as the machine form other company?

A: Since these machines have long history and are very popular in the market, it may be indeed possible that some machine models are similar as others. What we may think is that the machine model does not make big difference. And the criteria for machines may depend on the technical support and quality of the machines.

Q: How about your warranty?

A: Our warranty is 12 months. Normally,the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) We have dealers in some countries to offer compensable service.